HISTORY continued

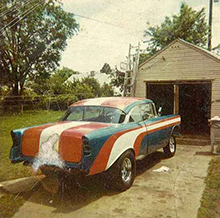

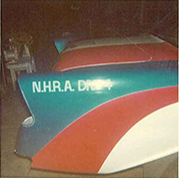

The next step is to paint the pearl white. The car was painted with Candy Apple Red and Candy Apple Blue over a gold base. This picture is right after we brought it home from Johnny’s shop. Wow…were we ever proud of that paint job.

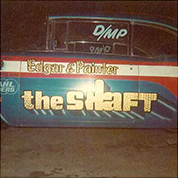

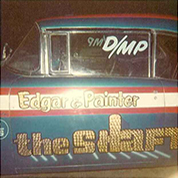

Next step is to the lettering shop. This was before the days of vinyl lettering. This is where you need to find a real artist. Johnny really liked Doughty who used to work on his own at his company called Western Art but now was working from Wren Sign Company in downtown Tulsa. This is in 1972 when everyone was naming their cars. On a trip a group of us took to the 1971 World Final in Amarillo, Paul McElwain who was another best friend of mine since elementary school came up with the idea of “The Shaft”. We told Doughty that we wanted the lettering to look like you were shooting the finger. As you can see in the pictures he did that with the “h” in shaft. We also told Doughty that we wanted Mighty Mouse standing on an elephant to signify a small block (mouse) motor killing a Chrysler Hemi (elephant). Johnny also painted my helmet to match the car and Doughty painted a hand shooting the finder on the back of it. I loved that helmet but it was stolen when I had some stuff stored in a mini storage building in Seminole, Texas. If anyone ever sees that helmet let me know because I sure would like it back.

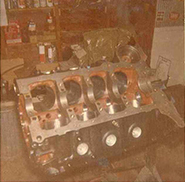

While the car was being painted we were working on our motor. We spent hours discussing what bore stroke combination we wanted to build. Our bible was “Chevy Power Guide Special Small Block Edition by Bill (Grumpy) Jenkins”, Engeldrum Publishing Corp., Northport, NY, 1971. There was a time that I could probably have cited each section of that book by memory. Jenkins was always reminding you to not forget about torque. So we decided to build a large bore short stroke motor using 6” rods. We decided we would find a 400” small block and put in a 283” crank. So with a 4.125” bore and a 3.000” stroke crank we would end up with a 325” motor that we felt it would deliver more torque than a 327” motor that had a 4.000” bore and a 3.250” stroke. Since Modified Production was a class based on pounds per cubic inch we thought we would make more torque than a guy we’d be racing that was running a 327” motor.

We found a 400” motor that had very little cylinder wall wear so that we could hone it to give us the clearance we wanted. It had 4 bolt main caps but we were going to have to do something with the crank bore to be able to utilize the small journal crank of the 283” motor. Bobby made the aluminum main caps out of some 6061-T6 stock and also made aluminum spacers to fit into the upper portion of the crank bore so the small journal crank could be used. Later spacer bearings were made for this application but this was years later.

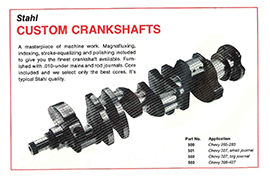

We spent hours cleaning and de-burring the block. We bought a 0.010”/0.010” Stahl crank. Did you know Stahl used to sell cranks?

Curt Dixon was running an A/MP Camaro out of Pryor, OK and we became pretty good friends with him during this time and we were talking to him about our motor and asking him who he would have do the heads. He told us about these two young guys that he had raced against that had this Maverick with small block in it that ran better than anything he had ever seen. There names were Cross and Reher. We found out how to get a hold of them and told them we had a set of double hump heads that we had converted to slant plugs and wanted to know if they would port them for us. We drove down to their shop on Arkansas Lane in Arlington, Texas. We met and talked to David Reher and Buddy Morrison and this little guy named Lee Shepherd comes out and talks to us and we left the heads with him. We had Lee do all the trick stuff to them. We angle milled them, put in screw-in studs with guide plates, removed the exhaust guide that extended into the port, did a 5 angle valve job, utilized small stem Manley valves, and did the trick hand ported and polished job that was second to none at the time.

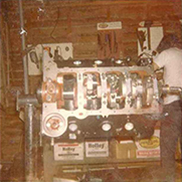

Now it’s time for assembly. We were using aluminum Superrods and TRW pistons. Check out the detailed assembly we were doing in my Dad’s garage. You can see his Water Wagon in the background. High Tech! We started off using an Edelbrock TR-1Y tunnel ram but then Edelbrock came out with the Grumpy Ram and we had to have it. We were even going to utilize a set of Dominators and reduce the bore to reduce the CFM but someone stole out of my Dad’s garage and we never did go down that road again and ended up with two 660 center squirters. Dominators on a small block. Hmmmm…seems like that’s what’s being done today.